The Heritage of Harris Tweed: Craft, Cloth and Character

Share

What Is Harris Tweed?

Few fabrics carry the heritage, texture and character of Harris Tweed. Known for its rich colours, durable weave and unmistakable charm, it is more than just cloth. It is a living tradition, shaped by the land, the weather and the people who make it.

The fabric was originally known as "tweel," the Scots word for twill, describing the way it is woven. According to popular legend, the name changed by accident in the 1830s when a London merchant misread a label, mistaking "tweel" for "tweed" — perhaps thinking it referred to the River Tweed. The name caught on and has been used ever since.

From Scottish Islands to The World

For generations, islanders in the Outer Scottish Hebrides wove tweed from local wool and natural dyes, making warm, hardwearing garments for their own use. But it was not until the mid-nineteenth century that Harris Tweed reached wider acclaim. Lady Dunmore, widow of the Earl of Dunmore who once owned the Isle of Harris, helped introduce the cloth to the mainland. Her influence brought it to the attention of a growing audience who admired its quality and connection to the landscape.

Today, Harris Tweed is the only fabric in the world protected by an Act of Parliament. By law, it must be dyed, spun and handwoven by islanders in their homes across the Outer Hebrides. This legal protection ensures every length of Harris Tweed remains tied to its roots — to the land, the craft, and the generations who continue to produce it with care and pride.

Handwoven to Perfection

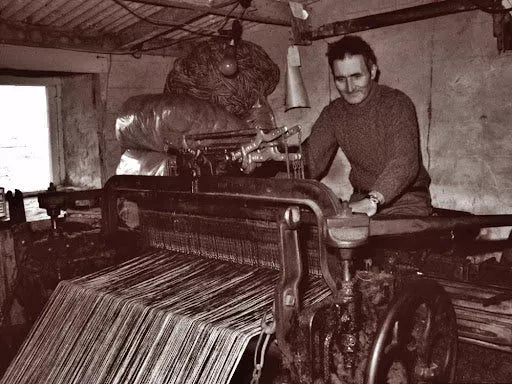

All Harris Tweed is handwoven on a treadle loom in the home of each weaver. Mill weavers typically use a modern double-width Bonas-Griffith rapier loom, while independent weavers often rely on the traditional single-width Hattersley loom, which has been used for generations.

Before weaving can begin, the weaver must carefully tie in the warp threads by threading the yarn through the heddle eyelets in a precise order. This meticulous preparation ensures the correct pattern and tension. As the weaving progresses, any breaks or mistakes are repaired by hand as they occur, preserving the quality and integrity of the cloth throughout the process.

Picture: A treadle loom

Once the weaving is complete, the cloth is carefully finished. It is washed and beaten in a solution of soda and soapy water to remove any dirt, oil or impurities. After cleaning, the fabric is dried, steamed, pressed and cropped to achieve its final texture and appearance.

The last stage is inspection by the independent Harris Tweed Authority, which visits the mills on a weekly basis. Each length of cloth is examined for quality and consistency. Only when it meets their exacting standards is it awarded the iconic Orb Mark, which is pressed onto the fabric as a seal of authenticity — a symbol recognised around the world as a guarantee of genuine Harris Tweed.

Picture: Harris Tweed Certification Label